DS Heaters' strip heaters, often considered component heaters, are a simple way of using surface area to transfer heat effectively. A fairly inexpensive way of heating surfaces or small areas, strip heaters are an excellent solution to meet any budget. If strip heaters are used as a radiant heater, they can have fins to maximize surface area and heat transfer to the air.

Construction

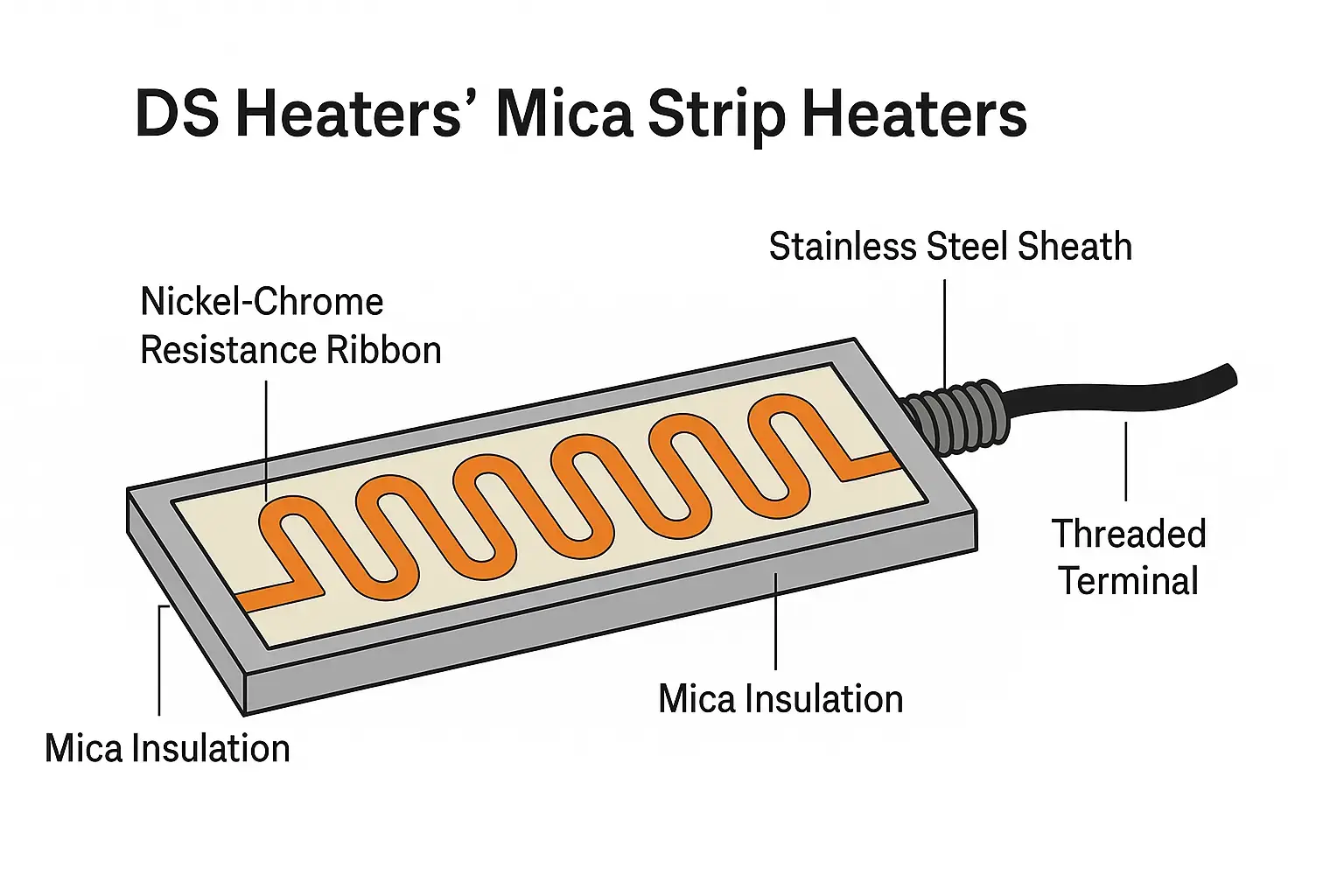

DS Heaters' Mica Strip Heaters are constructed by winding a nickel-chrome resistance ribbon around mica insulation and encapsulating it in a stainless steel sheath. They are available in an extensive variety of sizes and shapes, with options for holes, notches, and cut-outs. A range of threaded terminals, wire lead options, and terminal boxes provide great flexibility for field wiring. These heaters are ideal for plastic processing applications and for any application where heat is required on a flat or curved surface.

FEATURES

Heat up time is fast to provide a quick response to control input

The flat inner resistance ribbon generates a broad area of overall heat to put the heat source close to the work

Quality assembled winding and spacing of ribbon ensures maximum heat transfer and heater longevity

The Mica insulation also withstands high voltage temperatures, resist moisture, and remain immune to most chemicals